For many years, we have been proud to earn the trust of the country’s most reputable polymer component manufacturers, and Razin’s technological superiority has served to enhance customer competitiveness, preserve the environment, and support the development of entrepreneurship in the country.

The foundation of Razin Industrial Group’s excellence is defined as being based on reliable long-term business partnerships, achieving the highest level of production technology in quality and productivity, striving to provide the best services to customers, and ultimately having a constructive impact on building a dynamic and healthy society.

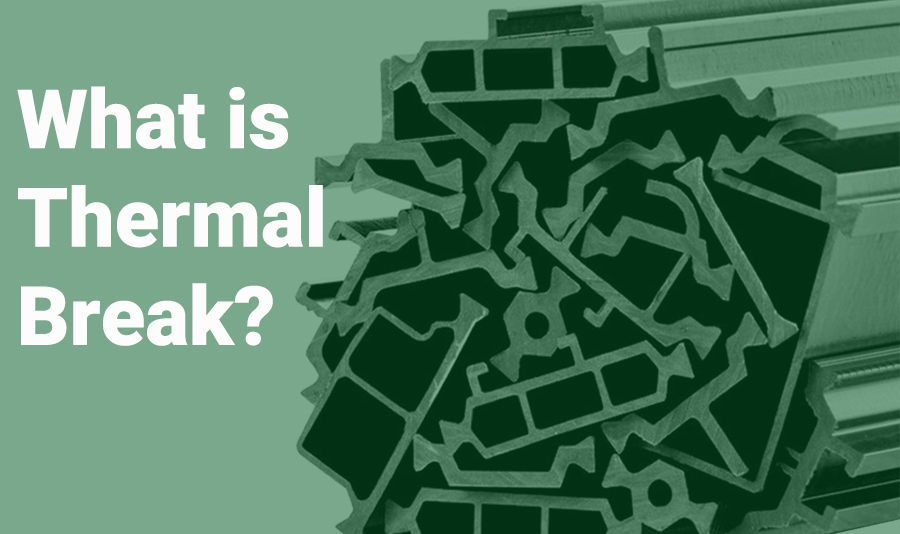

Part Razin Knowledge‑Based Company specializes in the production of polymer extrusion sections used in the building industry. The company manufactures various PA66 (polyamide 66) thermal break strips reinforced with 25% glass fiber, which serve as insulation barriers in aluminum thermal break profiles, offering diverse …

Part Razin Company, as the extrusion division of Razin Industrial Group, manufactures a wide range of thermoplastic elastomer (TPE) gaskets used in the automotive, home appliance, and construction industries.

Our gaskets are widely applied in UPVC profiles and aluminum door and …

According to national building regulations, the use of fire doors in emergency exits is mandatory. One of the key components of these doors is the intumescent or smoke‑seal strip.

Smoke‑seal strips are installed in the gap between the fire door and its frame and are designed to expand …

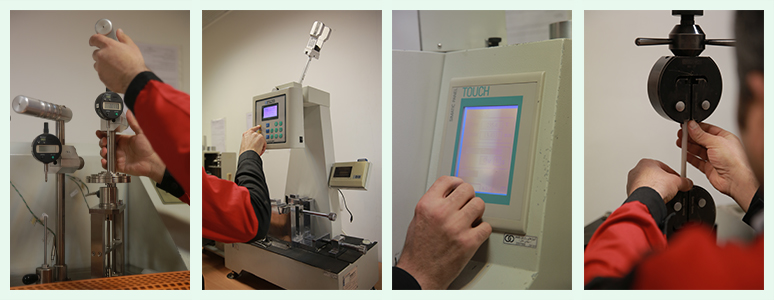

We have established a learning organization based on high technical competences and benefiting from creative and innovative human resources.With establishment of a comprehensive quality management system in our organization, we consider continuous monitoring of all processes to mitigate process risks and protect the interests of all stakeholders.

Part Razin Co, as the extrusion division of Razin Industrial Group, is a manufacturer of advanced thermoplastic profiles and gaskets with nearly two decades of experience in engineering plastics production.

The company benefits from top‑quality raw material sourcing, a state‑of‑the‑art polymer testing laboratory, a skilled research and development team, and modern production facilities enabling the manufacture of high‑quality thermoplastic profiles and gaskets for industries such as automotive, home appliances, and construction.